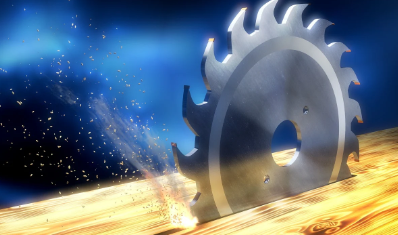

Edge Control

Redefined

Precision cutting is not only about sharpness. It is about balance, metallurgy, geometry, and the ability to perform consistently under pressure. Our cutting solutions are engineered to deliver controlled force, repeatable accuracy, and long-term durability across demanding environments.

From industrial fabrication to specialized craft applications, our blade systems combine advanced materials with refined edge profiling to ensure optimal performance throughout their operational lifespan.